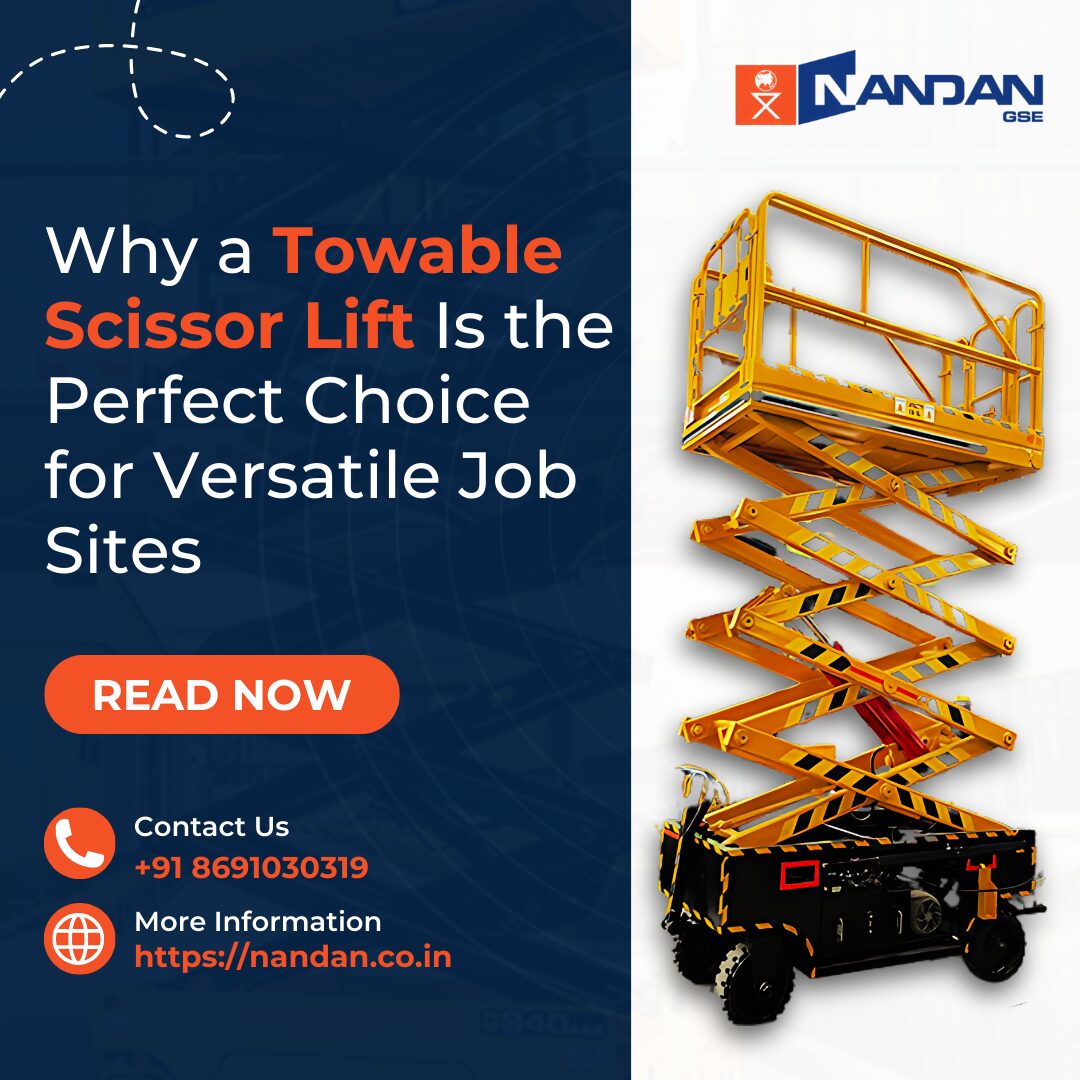

HEAVY DUTY SCISSOR LIFT

Nandan GSE: India's Leading Customizable Scissor Lift Manufacturer

Elevate your material handling to new heights with our Heavy-Duty Scissor Lift. Engineered to handle up to 40,000 kg with advanced PLC controls and motion sensors, this lift combines high-strength steel, chrome-plated cylinders, and robust safety features for unparalleled performance and reliability. Experience safer, more efficient operations with a design tailored to meet your specific needs, even in power outages.

PRODUCT DETAILS

- Designed & engineered to carry bulk loads of up to 40,000 kg

- Factor of safety 3 in all mechanical components

- Safety features in the equipment make it an accident-free environment.

- High Strength steel maximizes the load stability and extends the life of the scissor lift.

- Pilot check valve stops the lift in case of any untoward incident.

- Chrome plated cylinders with high strength pins give load strength and long life.

- Emergency hand pump helps in operation in case of power failure.

Different Scissor Lifts We Offer

Our Clients

Legacy Of 30 Years

With a rich history of over three decades in manufacturing and engineering excellence, Nandan GSE is a name you can trust. Our experience ensures you receive a product that meets the highest standards of quality.

Legacy Of 30 Years

With a rich history of over three decades in manufacturing and engineering excellence, Nandan GSE is a name you can trust. Our experience ensures you receive a product that meets the highest standards of quality.

Pan India Installation

No matter where you're located in India, our installation and servicing teams are equipped to reach you. We're dedicated to providing comprehensive support, no matter where your operations are based.

Pan India Installation

No matter where you're located in India, our installation and servicing teams are equipped to reach you. We're dedicated to providing comprehensive support, no matter where your operations are based.

Least Downtime

When it comes to your business operations, downtime is a costly concern. Our Heavy-Duty Scissor Lift is designed for minimal downtime, ensuring that your material handling processes run smoothly & efficiently.

Least Downtime

When it comes to your business operations, downtime is a costly concern. Our Heavy-Duty Scissor Lift is designed for minimal downtime, ensuring that your material handling processes run smoothly & efficiently.

Precision Motion

Features multiple scissors for synchronized lifting with advanced PLC controls and motion sensors.

Precision Motion

Features multiple scissors for synchronized lifting with advanced PLC controls and motion sensors.

High Load Capacity

Safely lifts heavy loads up to 40 tons, suitable for diverse industrial needs.

High Load Capacity

Safely lifts heavy loads up to 40 tons, suitable for diverse industrial needs.

Quality Materials

Constructed with Stainless Steel, Aluminum, and Flame-proof standards for durability.

Quality Materials

Constructed with Stainless Steel, Aluminum, and Flame-proof standards for durability.

Safe and Efficient

Designed to minimize human involvement, enhancing worker safety. Factor of safety 3 in all mechanical components for an accident-free environment.

Safe and Efficient

Designed to minimize human involvement, enhancing worker safety. Factor of safety 3 in all mechanical components for an accident-free environment.

Load Stability

High-strength steel maximizes stability and extends the lift's lifespan.

Load Stability

High-strength steel maximizes stability and extends the lift's lifespan.

Emergency Preparedness

Equipped with an emergency hand pump for operation during power outages.

Emergency Preparedness

Equipped with an emergency hand pump for operation during power outages.

Testimonials

Get In Touch With Our Team

Take the first step towards redefining efficiency, safety,

and innovation within your operations

Connect With Us: To learn more about how Nandan GSE can transform your material handling processes, contributing to the growth and success of your business!