About Nandan GSE

Since its inception in 1991, Nandan GSE has soared to unparalleled heights as a trailblazer in Aviation Ground Support Equipment (GSE) manufacturing and Hydraulic Lifting Systems. With unwavering dedication to innovation, precision engineering, and unwavering commitment to excellence, we have cemented our position as an international leader in the industry.

Vision & Mission

Our Vision

Our Mission

Nandan’s mission is to enhance customer productivity, performance, and safety through the delivery of superior products and solutions. We strive to provide optimal quality, reliability, and product lifespan, all while ensuring the utmost customer satisfaction.

Our People

Manufacturing Capabilities

Here’s an overview of our manufacturing capabilities from our perspective:

Factory Facilities: We operate two spacious factories near Mumbai. Our Khopoli factory covers an area of 40,000 square feet, while our Turbhe facility spans 60,000 square feet. Combined, our manufacturing facilities encompass 100,000 square feet, providing ample space for efficient production and assembly.

Full Fledged Manufacturing Set-Up: We have established a comprehensive and well-equipped manufacturing set-up. Our facilities are equipped with all the necessary infrastructure, machinery, and tools to support our manufacturing processes. From handling raw materials to final product assembly, we have the resources in place to ensure smooth operations.

3P Supply Chain Access: We have established partnerships with third-party suppliers under Non-Disclosure Agreements (NDAs). This allows us to access a reliable and secure supply chain network. Through these partnerships, we ensure a consistent flow of high-quality components and materials for our manufacturing operations.

Strategic Location: Our factories enjoy a strategic location near major transportation hubs. Situated close to Nhava Sheva Port, Mumbai Airport, and the National Highway, we benefit from convenient transportation of raw materials and finished products.

Advanced Machinery: Our manufacturing facilities are equipped with cutting-edge machinery and equipment. We have invested in specialized machines such as laser cutting, shot blasting, plasma cutting machines, CO2 MIG welding equipment, and EOT cranes. These advanced tools enable us to achieve precision fabrication and enhance manufacturing efficiency.

Skilled Manpower: Our team consists of over 250 highly skilled professionals who play a vital role in our manufacturing operations. From trained technicians to experienced engineers, our workforce possesses the expertise needed to drive our production processes forward.

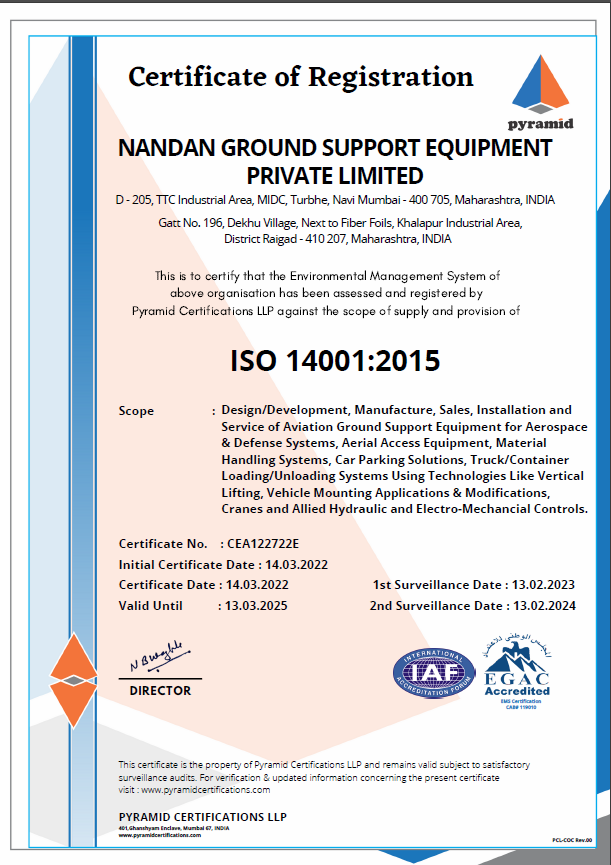

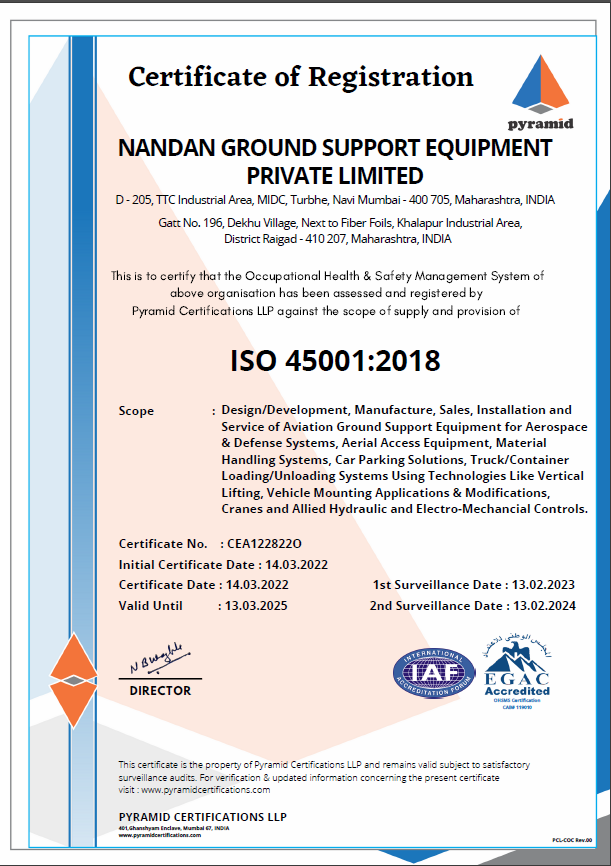

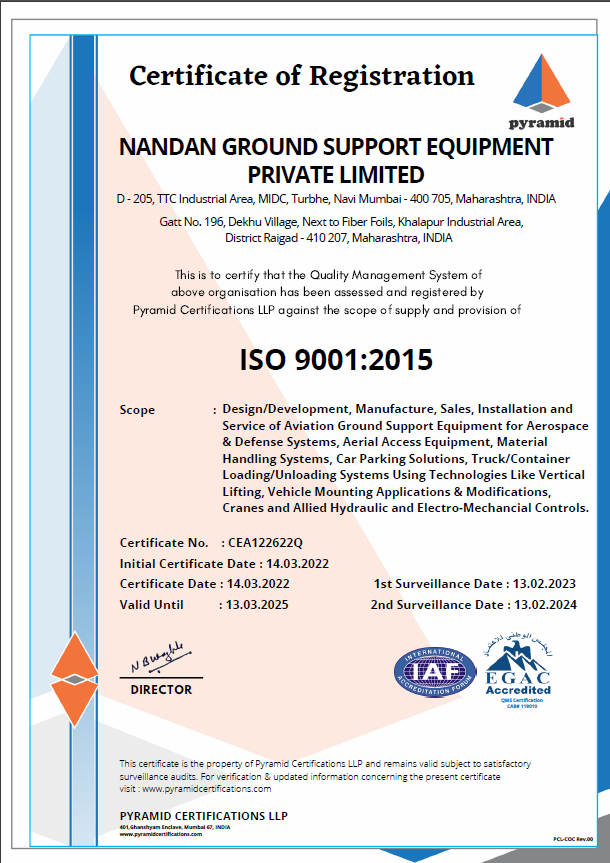

Quality Certifications: Quality management is of utmost importance to us. That’s why we have obtained certifications such as ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018. These certifications validate our commitment to maintaining international standards for quality, environmental management, and occupational health and safety. We are one of the rare firms in India to get all three ISO Certifications.

Welding Standards: Our welding processes adhere to the stringent standards outlined in AWS D1.1 (American Welding Society D1.1). This ensures that our welding procedures meet the required specifications in terms of strength and reliability.

Compliance with Standards: In addition to AWS D1.1, we also adhere to relevant MIL (Military) standards. By following these standards, we ensure that our products meet the stringent requirements of the military and defense industry.

IATA AHM 2022: We comply with the International Air Transport Association (IATA) Airport Handling Manual (AHM) 2022 standards. This certification assures our customers that our ground support equipment solutions meet industry guidelines and specifications.

Registrations: We are proud to be registered with various esteemed industry organizations and associations. These include the Society of Indian Defense Manufacturers (SIDM), National Small Industries Corporation (NSIC), GeM (Government e-Marketplace), and the Aerospace & Defense Consultants Association of India. These registrations highlight our credibility and commitment to the aerospace and defense sectors.

Licensed Software: For our design processes, we utilize licensed software such as Solidworks and AutoDesk. These industry-standard software tools empower us to create precise and innovative designs for our material handling equipment & ground support equipment and solutions.